Good day everyone. All protocols duly observed. I want to appreciate the organizers of this 2020 soapboxscience event for the opportunity to present our activities in our research group (SwWECh) despite the outgoing Pandemic experience. I really appreciate the doggedness of the organizers.

I will be speaking briefly on the title: WASTE TO WEALTH: IMPROVING QUALITY OF LIFE THROUGH WASTE MANAGEMENT, A MULTI -ACHIEVEMENT APPROACH.” . Yes, waste to wealth in the sense that our own raw materials are those things discarded as waste. Therefore discarded bottled water Plastic bottles, cocoa husk wastes, Snail Shells, periwinkle shells are some of the waste to be turned to new products.

Also, this talk is multi- achievement because it involves conversion /management of discarded solid wastes to useful product such as adsorbents for the treatment of water and waste water. In other words our approach is solving the problem of solid waste management, wastewater treatment and water and sanitation issues.

Plastic Wastes

The durability and comfort associated with plastic usage and handling has promoted its adoption for use, however, these usage has not come without its challenges, manifested as plastic pollution. Plastic pollution can afflict land, waterways and oceans. Living organisms, particularly marine animals can be harmed either by mechanical effects, such as entanglement in plastic objects, problems related to ingestion of plastic waste, or through exposure to chemicals within plastics that interfere with their physiology. Effects on humans include disruption of various hormonal mechanisms. Primary sources are the waste plastics from the manufacturing industry, and secondary sources are plastic litter – bottles (Polyethylene Terephthalate (PET)), food packaging, polyester clothing, fishing line. An estimated amount of 1.1 to 8.8 million tonnes of plastic waste enters the ocean from coastal communities each year (Jambeck et al., 2015). As of 2018, about 380 million tonnes of plastic is produced worldwide each year.

Environmental impacts of plastics

Plastics causes nuisance in the environment and damage the aesthetics of the environment.

Burning plastics releases pollutants into the atmosphere that damages air quality, and releases oxides of carbon that in turn drives climate change upon reaction with free oxygen

Plastics blocks the waterways, and disallows free flows, thus causing stagnation of water, which can in turn become breeding grounds for mosquitoes, and consequently malaria, and health impact on humans.

When plastics finds its way into our oceans, it causes impacts like entanglement and ingestion by wildlife in the environment. These plastics and associated chemicals therefore gets when ingested by marine organisms which then bioaccumulates in the food chain (Teuten et al., 2009), and consequently gets passed onto consumers in the higher food chain including humans when they consume these marine lives.

Also, there are several chemicals within plastic material itself that have been added to give it certain properties such as Bisphenol A, phthalates and flame retardants (Das and Kumar, 2015). These all have known negative effects on human and animal health, mainly affecting the endocrine system. There are also toxic monomers, which have been linked to cancer and reproductive problems (Koushal et al., 2014).

These unwanted realities suggest the need to manage plastic wastes in our environment. Eradicating the production and even single usage of plastic seems to be the best option to eliminate the menace of plastic in the environment. However, accepting this option is taking longer time for adoption, thus the need to find alternative usage for plastics, to reduce its environmental and health impacts, and we have identified activating it for use as adsorbent.

Production of PolyethyleneTerephthalate (PET):

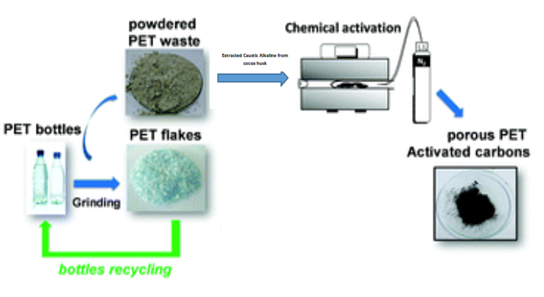

This involves processes such as sorting, cutting, washing , drying, impregnation with alkali and washing to neutral off, oven drying and carbonization. The powder obtained from carbonization process can be used for adsorption purposes. This process is used to cleanse our water supply and wastewaters, by removing contaminants (organic and inorganic) from them even at low concentrations, before being discharged to our water bodies.

Production of PET based Activated Carbon

Cocoa Pod Husk

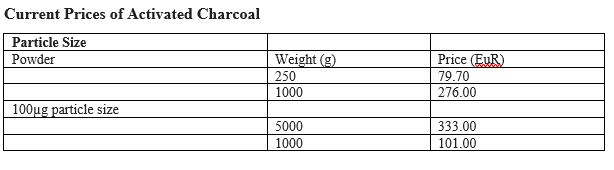

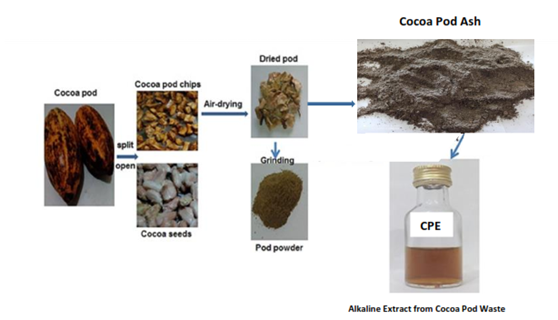

Nigeria is a major producer of cocoa. The husk is a major constituent of the cocoa pod and extracts from has numerous applications in textile manufacture, pulp and paper production, reclaiming of rubber, food production, detergents and soap production as well as laboratory reagents. Generally cocoa is processed by rural farmers, mainly women especially in soap production. The husks are heaped and allowed to undergo natural decay, constituting an environmental nuisance by impairing on the aesthetics of the environment and unpleasant to sight, serving as breeding ground for mosquitoes, contributing to the emission of greenhouse gases like methane, which is a major driver of global warming, with a heat trapping potential that is over 20 times more than carbon dioxide. Ash from cocoa pod has been the main source of alkali for the production of the local black soap in Nigeria. However, the black colour of the soap does not make it attractive and acceptable to all. This limits the sales of this product to the society who use imported products as alternatives. In our project, the cocoa pod husk has been processed to alkali quality with enhanced aesthetics that will not make the soap black. The equivalents of our product to the imported potassium and Sodium hydroxides are also known. 250g of sodium hydroxide costs 44.8 EuR and 500g costs 80.2 EuR.

Our alkali has been used successfully as activating / impregnating agent in the production of adsorbents for water and wastewater treatment. The environmental problem caused by the heaped decomposing cocoa husk can therefore be solved by extracting caustic alkali for industrial applications without the attendant black colour (Okoya (1987); Okoya and Ogunkoya, 2009)

The production of caustic alkali involves collection and sorting out of the husk followed by processes such as drying, pulverizing, sieving, ashing, evaporation.

Production of Caustic Alkali from Cocoa

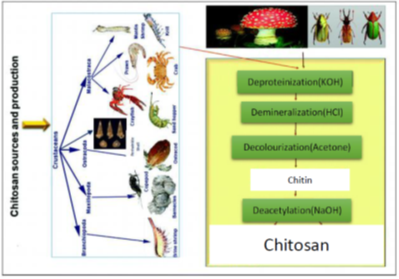

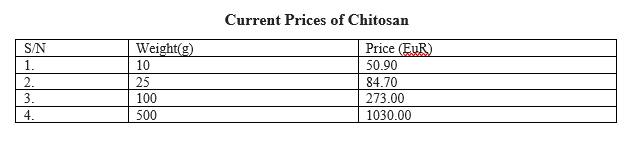

Periwinkle Shells Periwinkle shells are waste obtained from periwinkle. Periwinkles are marine mollusks (gastropods) with thick spiral shells. As they grow, gastropod shells follow a mathematically regular pattern. Thus, as they increase in size, they retain their basic form [Agbede and Manasseh, 2012]. Although, few people utilize the shell as coarse aggregate in concrete in areas where there are neither stones nor granite for purpose such as paving of water -logged areas [Olutoge et al. 2012]. The use of periwinkle shells will add economic value; provide a potentially inexpensive material that will be used for the removal of metal ions from aqueous media and help reduce the cost of waste disposal. Therefore, our research group has produced the expensive chitosan from both periwinkle and snail shells and used same as adsorbents and also as adsorbent modifier for water treatment (Okoya et al., 2016). Also periwinkle shells alone has been developed as low-cost adsorbent for the recognition and removal of Cr (II) and Zn (II) ions from aqueous media. (Awokoya et al., 2016). The production of chitosan encompasses the following processes: Grinding of the Periwinkle shell, Sieving, Deproteinisation, Demineralisation, Decolourisation, and Deacetylation. The Chitosan formed can be used for remediation of both organic contaminants and inorganic contaminants from waste water. They can be individually used as an adsorbent and can also be blended with other materials to form composites that enhance sorption properties.

Processes Involved in Chitosan Production

REFERENCES

Okoya, A.A. (1987): Extraction of Caustic Alkali from Cocoa-pod husk. B.Sc. Project.

Okoya, A. A. and Ogunkoya L. (2009): Environmental management and evaluation of Cocoa-pod husk waste. In: Proceedings of the Third World Organization for Women in Science. (TWOWS) African Regional Conference. Theme: Gender and the Millennium Development Goals (MDGs) (eds.) November 16th – 20th, 2009, ECOWAS Commission, Asokoro, Abuja, 481-488, NIGERIA.

Agbede OI, Manasseh J. Suitability of periwinkle shell as partial replacement for river gravel in concrete. Leonardo Electronic Journal of Practices and Technologies. 2009; 15:59-66.

Olutoge FA, Okeyinka OM, Olaniyan OS. Assessment of the suitability of periwinkle shell ash (PSA) as partial replacement for ordinary portland cement (OPC) in concrete. International Journal of Research and Reviews in Applied Sciences. 2012; 10:428-433,

Okoya, A. A. , Akinyele, A. B., Amuda, O. S. and Ofoezie, I. E. Chitosan-Grafted Carbon for the Sequestration of Heavy Metals in Aqueous Solution American Chemical Science Journal 11(3): 1-14.

Awokoya, K.N., Sanusi R. O. and Oninla V. O. and Olumuyiwa M. Ajibade (2016) Activated Periwinkle Shells for the Binding and Recognition of Heavy Metal Ions from Aqueous Media International Research Journal of Pure &Applied Chemistry 13(4): 1-10.

Jambeck, Jenna R., Geyer, Rowland, and Wilcox, Chris (2015). Plastic waste inputs from land into the ocean. Science. 347 (6223):768-771.

Das, M. P., and Kumar, S. (2015). An approach to low-density polyethylene biodegradation by Bacillus amyloliquefeciens. Biotech 5, 81-86.

Kousal, V., Sharma R., Sharma M., and Sharma V. (2014). Plastics: Issues, Challenges and Remediation. Inter. J. of Waste Resources 4:134. Teuten, E. L., Saquing, J. M., Knappe, D. R., Barlaz, M. A., Jonsson, S., Björn, A., Rowland, S. J., Thompson, R. C., Galloway, T. S., Yamashita R., Ochi, D., Watanuki, Y., Moore, C., Viet PH, Tana TS, Prudente M, Boonyatumanond R, Zakaria MP, Akkhavong K, Ogata Y, Hirai H, Iwasa, S., Mizukawa, K., Hagino, Y., Imamura, A., Saha, M., Takada, H., Philos Trans, R. Soc Lond, B. (2009). Transport and release of chemicals from plastics to the environment and to wildlife. Biol Sci., 364(1526):2027-45.